Cold Repairs In The Body Shop & Glue Pull Repair Technology

Liability for body-shop owners is real. Nobody wants to see a judgment against them, especially if the problem is preventable.

But “preventable” can entail many things. If the shop owner and his/her employees do not know the most up-to-date body repair techniques, preventing problems immediately becomes more difficult. This goes even further. OEM’s also need to be aware of the rapidly changing body-repair scenario to avoid liability and loss of customers.

KECO technology is all about avoiding problems, making jobs easier, helping establish great customer relationships, working with insurers for the best outcome, and above all, performing great repairs at reasonable costs.

Yesterday Vs. Today

Today’s vehicles are more complicated than ever. Electronics are everywhere, from standard electric windows and doors to keyless entry to anti-theft and anti-collision systems. This includes what used to be relatively simple items: body panels.

In the past, a body panel was simply a painted piece of sheet metal. Today’s panels may be constructed of a composite, plastic, steel, aluminum, or a combination of these materials. Panels may be painted conventionally but they may also have an e-coat on the outside surface and an anti-corrosion coating and insulation on the inside. Then there are the panel electronics. Newer cars and trucks have sensors that cover the perimeter of the vehicle and are used for parking assistance, blind-spot monitoring, and lane-departure and pre-collision alerts. What used to be a simple piece of metal is now a sophisticated section of the vehicle that performs many functions in addition to the traditional one: serving as a body or wheel covering.

It’s easy to see how a technician, without knowing how to address body panel problems correctly, whether they were caused by an accident, a scrape, scratch, or wear and tear, can mess up the body panel with the result that the owner is unhappy with the repair, inviting problems like complaints, lawsuits, and loss of customers and profits.

The main reason for poor repairs and the loss associated with them is attempting to repair a contemporary body panel with outdated methods. Traditional body repair methods involve heat: drilling holes and then welding studs or attaching keys to the panel in order to pull out a dent. This worked great when body panels were simply a piece of sheet metal with nothing problematic behind the panel and nothing on the surface except primer and paint to worry about. And when the repair was complete, the tech just finished up by filling, priming, and finish coating.

If a technician attempts a traditional stud/wiggle wire/weld key method on a contemporary body panel, s/he immediately runs into concerns. You can’t just drill into the panel without knowing what’s behind it. You can’t just weld in studs – what if in back of the panel are wires, insulation, or sensors that could be affected, lights that could be damaged, or anti-corrosion material that could catch fire? Even if you were able to somehow use this traditional method on a contemporary panel, what about the e-coat on the surface?

Welcome to cold repairs.

New Technology

KECO glue-pull repair (GPR) methods (cold repairs) are revolutionizing body panel repairs because they eliminate drilling and welding while lessening the need for filler, priming, and surface remediation.

When the technician employs GPR techniques, s/he glues a removable attachment, called a tab, to the panel surface and pulls the dent out specially designed KECO Tab pullers and muscle power. Once the dent is pulled, the tech removes the adhesive and the tab.

This non-intrusive method not only avoids drilling into the panel and subsequently welding studs then fixing both these incursions, but it also greatly lessens the potential to damage the panel surface, which means less need to re-e-coat and less priming and painting.

KECO methods yield many benefits, in addition to less work and better results. Traditional methods remove the paint and any surface protection. If the shop returns the vehicle to the owner by simply filling, priming, and painting the surface, the OEM protection is gone. This leads to more corrosion and eventually a diminished life span for the vehicle. “Cold repairs” i.e., glue pulling, allows most if not all of the surface protection to remain, depending on the extent and size of the repair. When a shop uses GPR, they return the vehicle close to OEM specs and thus the protection remains, and as well as the normal vehicle life span.

OEM firms need GPR methods and the benefits they provide because they are the methods and techniques of the future. GPR included in repair manuals greatly increases technical knowledge and methods before untrained or unknowing personnel can inflict damage on a vehicle and the customer problems associated with it.

Aluminum & Steel

Car and truck manufacturers have used aluminum in the past for body panels and structural members. But today they are using this metal as a mainstay because it is one of the easiest ways to reduce the weight of a vehicle and therefore reduce fuel consumption. For example, the most popular vehicle on the road, the Ford F-150 pickup now uses aluminum alloy in all of its body panels and for the truck bed with up to 29% better fuel economy and with the same strength of parts. (In 2013 Ford’s CEO, Alan Mullaly, said that “pound for pound, aluminum is stronger and tougher than steel.”) It appears aluminum body material is here to stay. Does this mean that now body shops are compelled to have separate aluminum and steel work areas and to buy separate tools to perform the work? Unfortunately, with conventional body repair techniques, the answer is yes. With KECO’s GPR principles, it’s an emphatic and grateful “no.” GPR does not require separate tools or work areas because glue pulling works the same on both aluminum and steel. The techniques are the same, the methods are the same and the tabs, glue, and pullers are the same.

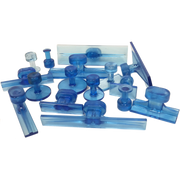

What’s more, KECO tools, tabs, and accessories are reasonably priced so shops do not have to make large monetary investments. A beginner kit, the KECO Glue Pulling Collision Starter Kit costs only $199.99 and it utilizes your existing frame machine, chains, rope, and ratchet or anything you have to pull with. The next step up, the KECO Tab Glue Pulling K-Bar Collision Kit (#1) is only $475 and includes everything a tech needs to begin the advanced art of glue pulling while leaving behind the more time-consuming, labor-intensive traditional methods of drilling and stud welding for the more efficient, less intrusive GPR.

Techniques are simple enough that a technician can learn to glue pull damaged panels the day their new tools arrive. Simplicity and efficiency together make KECO glue pulling the method your shop will want to have, in fact, will need to have in order to keep pace with the body-panel repair transformation that the current state of automotive design and manufacturing is undergoing.

KECO recommends either the above mentioned K-Bar Collision Kit (#1), the Collision Pro Kit (#2), or the all-pro Collision & Hail Manager Kit to start your shop in the GPR techniques. The Collision Pro Kit (#2) at $1,390 includes the following:

- K-bar leverage bar with adaptors

- K-beam bridge lifter with adaptors

- Cool/warm offset PDR light

- Glue gun

- Glue sticks (two kinds)

- Slapper hammer with puck

- Slapper body spoons (combo pack)

- Glue tabs (various styles)

- Toolbag

The K-Bar Collision Kit (#1) includes:

- K-bar leverage bar with adaptors

- Glue gun

- Glue sticks (two kinds)

- Glue tabs (various styles)

- Toolbag

The Cadillac of GPR kits is the Collision & Hail Manager kit for $2,450. It includes the following:

- K-bar beam bridge lifter with adaptors

- K-bar leverage bar with adaptors

- Robo mini dent lifter

- 1-pound aluminum slide hammer with 2 adaptors

- Slide hammer adaptor

- Super tab adaptor

- U-bolt adaptor

- Warm center offset PDR light

- Cordless glue gun

- Adjustable temperature corded glue gun

- Three ten packs of glue sticks (three varieties)

- Blending hammer

- Composite slapper hammer with puck

- Crown slapper plastic body spoons (combo pack

- Knockdown tip holder

- Interchangeable micro knockdown tips (5 pack)

- knockdowns in sizes ranging from 3/32" (2.5 mm) to 1/4" (6 mm)

- glue tabs: dimpled hail, smooth, ice smooth dual size crease and flip tabs, flexible and rigid, centipede, and modular

- various adaptors

- tool bag

All kits ship free direct from KECO.

Check out our website for demonstration videos and additional information about all the great tools and accessories KECO has to offer.

Classes & Training

To really do it right, especially for OEMs, discover KECO training classes. We offer in-depth knowledge, techniques, and tips. Most importantly we share our experience so your staff can learn from the best. These one-, two-, or three-day courses are taught on-site by our knowledgeable team, which means your personnel learn the latest, most efficient body-repair techniques in the comfort and familiarity of their own work environment.

Our techs love their work and it shows. They teach everything from how to prepare surfaces to which glue and tab is best for which application to pulling in difficult areas.

OEMs need to know KECO techniques and methods, especially so they can include it in the information they provide to OEM techs in repair manuals. Cutting-edge body repair now means glue pulling, so consider taking advantage of the years of know-how and experience KECO has to offer in their classes. It will pay big dividends down the road for dealers and large and small shops as aluminum becomes more of the material of choice but also for more efficiently and economically repairing dents and scratches on steel body panels, without welding and drilling.

Classes are available to shops and manufacturers no matter what their training budgets. Click here for more information.

From OEM’s to traditional mom-and-pop corner body shops, KECO is here to serve you, to make your work easier with less effort, to make it more efficient while being able to do more work in less time, to gain more customers who are happy the first time (and who will tell their friends), to avoid liabilities and the headaches that they produce, and to increase profits so you can provide the best service you can and continue to do the work you love. With more efficiency and higher profits, not only do you gain but your technicians gain as well. They see an immediate benefit with GPR methods because they are on the front line, doing the work. The effect is clear and potent. So make it a point to contact KECO now so you, your customers, and your technicians can begin enjoying the benefits of GPR today.

Leave a comment